Why us

Numbers & Statistics:

- Daily production of up to 10,000 blocks.

- Ready-mix concrete production capacity of up to 120 cubic meters/hour

Client Testimonials:

Success stories from major clients like Alfanar and SAPAC.

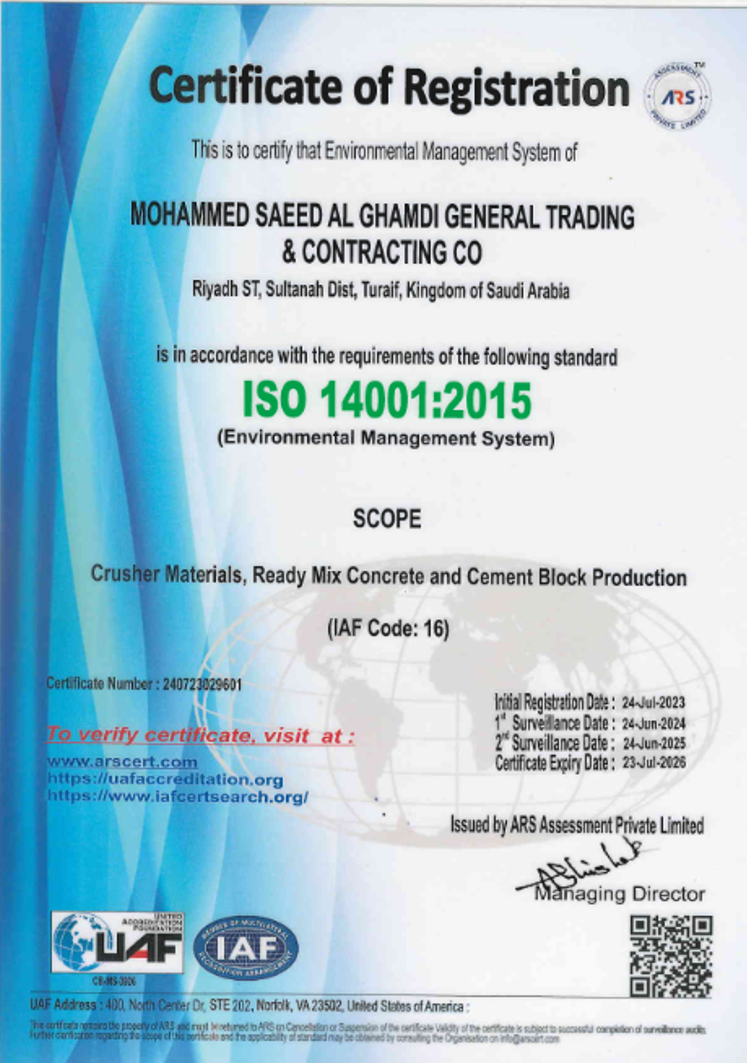

Quality & Certifications:

A dedicated quality control laboratory conducting tests as per international standards (ASTM).

FACILITIES

MSG READY MIX CONCRETE BATCHING PLANTS:

MSG R.M.C. Batching Plant, established in 1990, initially installed a 24-meter concrete pump to meet industrial and commercial demands. Over time, MSG upgraded the batching plant with modern pumps and mixers. The main batching plant has a production capacity of 100 cubic meters per hour, while the additional plant in Turaif boasts a capacity of 120 cubic meters per hour. Additionally, MSG owns a mobile batching plant that can be deployed on-site as needed, with a production capacity of 80 cubic meters per hour.

In an effort to achieve the high quality, MSG Concrete Factory is the first in the region to achieve the Saudi quality mark.

Saudi Standards, Metrology and Quality Organization SASO

MSG BLOCK MANUFACTURING UNITS:

MSG Block Unit established production in 1982 with the installation of the region’s first automatic block machine in Turaif. Over time, the unit upgraded its machinery, including modern equipment such as forklifts and cranes. Currently, the daily production capacity stands at 10,000 blocks. In response to growing client demand, MSG is establishing another manufacturing unit in Turaif, equipped with state-of-the-art automatic machines, forklifts, and cranes. This new unit is also projected to produce 10,000 blocks per day

MSG AGGREGATE CRUSHERS:

MSG Crusher no. 1

In 2004, MSG established an aggregate crusher in the Al Hammad area (Rich in BASALT STONE), approximately 70 km from Turaif. The crusher, equipped with modern machinery, aims to exceed production demand efficiently. It currently produces commonly used aggregates for ready mix concrete and block manufacturing, including ¾” coarse aggregate, 3/8” coarse aggregate, and manufactured sand. The daily production capacity of this crusher is 1800 cubic meters.

MSG Crusher no. 2

In 2011, a second crusher was established in Al Hammad area, adjacent to crusher no. 1. Its primary purpose is to provide comprehensive support to the WAAD AL SHAMAL PROJECT clients. The new crusher produces Ballast, Sub-Ballast, Granular Backfill, Aggregate Sub-Base, And Coarse Aggregate, as well as fulfilling specific requests for ready mix concrete and block manufacturing. Crusher no. 2 has a daily production capacity of 3000 cubic meters. Both crushers exclusively use basalt aggregates that meet local and international standards.

MSG QUALITY CONTROL LABORATORY:

In order to ensure the highest quality standards, we have established an on-site quality control laboratory at the plant. This facility rigorously tests aggregates according to international standards. Additionally, we monitor the quality of ready-mix concrete daily by assessing workability at the batching plant and conducting compressive strength tests on samples.

In an effort to achieve the high quality, MSG Concrete Factory is the first in the region to achieve the Saudi quality mark.

Saudi Standards, Metrology and Quality Organization SASO

THE BELOW QUALITY TESTS OF AGGREGATES ARE PERFORM WEEKLY

| CONCRETE SPECIMEN COMPRESSIVE STRENGTH | ASTM C-39 |

| SIEVE ANALYSIS OF COARSE AND FINE AGG | ASTM C-136 |

| SAND EQUAVALENT TEST OF FINE AGGREGATE | ASTM D-2419 |

| SOUNDNESS OF AGG. BY SODUIM SULPHATE | ASTM C-88 |

| FLAKINESS AND ELONGATION OF AGGREGATES | ASTM D-4791/BS 812 |

| SPECIFIC GRAVITY OF COARSE AGGREGATES | ASTM C-127 |

| SPECIFIC GRAVITY OF FINE AGGREGATES | ASTM C-128 |

| CHEMICAL ANAYLIS OF WATER | |

| BULK DENSITY OF BLENDED C.A. | ASTM C-29 |

| LOS ANGELOS ABRASION TEST OF C.A. | ASTM C-131 |

| CLAY LUMPS AND FRIABLE PARTICLE IN AGG. | |

| MATERIAL FINER THAN 200 NO. SIEVE |